Maintenance Consultancy

- Services

- Maintenance Consultancy

Asset Reliability Optimization

In an increasingly competitive global market with shrinking margins and even tighter profits, owners of asset-intensive operations can no longer ignore the value of asset maintenance management.

Suboptimal maintenance decisions cost plants and other industrial facilities hundreds of millions of dollars annually in equipment downtime and failure, reducing productivity, catalyzing premature replacement cycles and potentially damaging customer goodwill.

- Preventive Maintenance (PM) Optimization

Plants that engage only in preventive maintenance primarily are devoid of systematic processes to track their PM activities effectively. This leads to PM being performed too often or too little which leads to equipment failure and shortened life.

MaintenancePro Africa provides the optimal preventive maintenance interval that considers the equipment reliability, spare parts planning, maintenance interventions and expected asset availability

- Data-driven decision support

Recent developments in data and communications technology lay an opportunity for companies/plants to collect an unprecedented amount of data. Various data such as failure events, condition monitoring, production data, operational data and resource data can be exploited to provide maintenance and operations decision support while improving the performance of the assets.

MaintenancePro Africa utilises data mining, machine learning, and diagnostic and prognostic statistical applications to guide organisations toward the future of asset management by incorporating these data-driven technologies into existing asset management processes

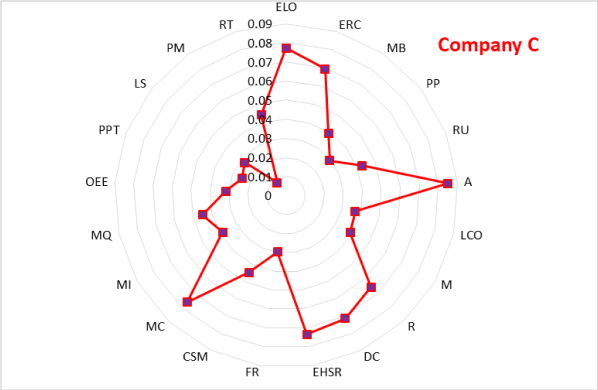

Maintenance Objectives and Key performance indicators (KPIs)

The maintenance objectives address decision support aspects, including equipment life cycle, maintenance cost management, and asset performance and also articulate the overarching strategy of the maintenance function in the organization. Most Industrial set up derive maintenance objectives exploiting educated guesses or historical usage without substantiating the basis of selection and use.

MaintenancePro Africa will assist organisations in deriving the optimal maintenance objectives anchored to the organizational goals. We offer a systematic approach that also assists organisations in tracking the evolvement of increasing and diminishing objectives in terms of importance. Ultimately, we will guide organisations to align them towards the maintenance strategies employed and eventual exploitation for maintenance optimization programs.

Inventory Optimisation

Spare parts, materials and supplies for MRO (maintenance, repair and operations) often represent millions of dollars in inventory. However, most of the inventory remains unused, locking up working capital year after year. Moreover, spare obsolescence, expiry and pilferage creep in leading to significant losses in terms of spares and operational deficiency. More often, locating the right items and replenishing as required becomes a challenge, creating production delays and encouraging the stocking of duplicate parts, not to mention overstocking.

MaintenancePro Africa has developed an intensive approach to Inventory Optimization that leverages physical, procedural and technological enhancements To help companies increase inventory (raw materials, WIP, finished goods and MRO) efficiency and optimize costs.This framework provides visibility and control to the organization to optimize inventory, eliminate stockouts, enhance planned preventive maintenance, reduce working capital requirements and concentrate on the core activities.

Joint Maintenance and Spares optimization

While considering optimal maintenance management strategies, using spares motivates joint maintenance and spares policies.

An integrated framework for the joint optimization of maintenance and spares policy is developed here to inculcate the prescription of elaborate corrective maintenance strategies addressing imperfect maintenance (imperfect diagnosis and repair) and their interactions.

Asset Life Optimization

Industrial setups as end-users with equipment approaching their end of life retain a significant responsibility in arriving at sustainable decisions related to asset maintenance, life extension and ultimately, disposal. There is a need for life-extension strategies and inventory strategies aligned to mitigate probable unexpected and involuntary obsolescence are advocated. Moreover, a key aspect to extend BS EN 13306 retains sustainable maintenance, where equipment life extension strategies like remanufacturing are integrated with maintenance and robust spare parts replenishment policies.

MaintenancePro Africa provides an opportunity towards the development of new sustainable maintenance methodologies/models considering maintenance and remanufacturing impacts within conventional maintenance policies to mitigate the environmental and economic effects in the transition towards sustainability

Simulation and optimization

Simulation is a model-based method that may include mathematical and simulation-based methods to derive decision support for any industrial problem. The system unites the activities and efforts of maintenance, operations and inventory departments delineating opportunities to harness internally and externally and reveal common goals and best practices.

MaintenancePro Africa uses simulation model approach, which explicitly models the different maintenance strategies like corrective, preventive and condition-based maintenance policies enabling to derive the optimal maintenance effect on production quality, throughput and capacity and optimize the same for high asset performance and production.

Other Consultancies

- Market feasibility

- Research-based consultancy

- Project-based consultancy

Lubrication

Our team of qualified lubrication consultants have nearly 40 years combined experience working with industrial customers, whose sectors include cement, food & beverage, mining, power, pulp & paper.